Introduction

Insulators are an essential part of electrical engineering. You cannot except for any electrical project without using an insulator. The main purpose of the insulator is to provide electrical isolation between different parts of electrical system. Insulators provide resistance in a circuit to minimize the flow of current. In a high voltage transmission line, the importance of the insulator increases significantly. In the transmission line, insulators minimize leakage current into the poles. The main insulators in high-voltage transmission lines are Suspension insulators, Post insulators, and pin insulators. This article will teach you about insulators used in high-voltage electrical transmission lines.

Suspension insulator

Suspension insulators are made from porcelain material. These porcelain posts are in the form of a single disc or a string of multiple porcelain discs. And these insulating discs are hung down on an electrical pole. The basic purpose of a suspension insulator is to provide support to the high-voltage transmission lines and is also used to separate high-voltage transmission lines. The voltage limitation of the suspension insulator is more the 33000 VA.

The flexibility of suspension insulators

Sometimes suspension insulators are also known as “String type Insulators.” Suspension insulators are very flexible, and you can modify them according to the need of electrical system. For example, suspension insulator discs are made with a porcelain insulator material. Each porcelain insulator disc can handle up to 11000 VA at a time.

If the electrical system requires high VA (Power) demand, you can increase the capacity of the suspension insulator by adding more porcelain insulation discs. If in a suspension insulator, three discs are used, then the ability of the three-disc suspension insulator increases up to 33 KVA. Similarly, if the electrical system requirement is to handle up to 132 KVA, you have to make a string of 12 porcelain discs (12 x 11KVA = 132 KVA).

What are the different parts of suspension insulators, and how are they made of?

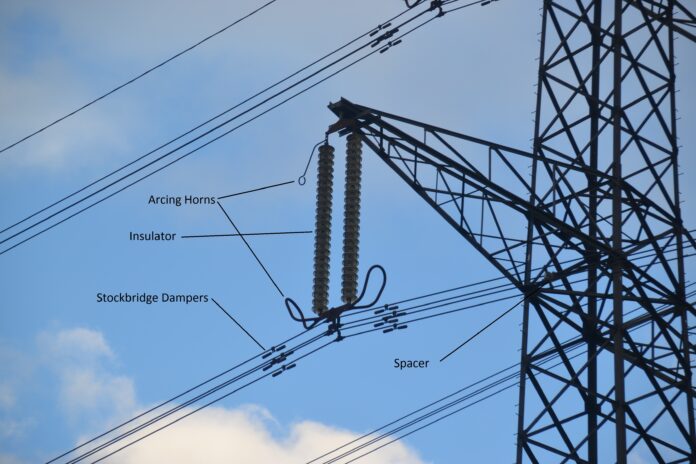

Parts of suspension insulator

The construction of suspension insulators is straightforward to understand. Any suspension insulator consists of two parts. The following are the name of these two parts:

- Insulation discs

- Metallic links

- Cross arm

Construction of suspension insulators

For constructing a suspension insulator, multiple insulation discs are connected with the help of metal links. All the insulation discs are attached in series strings. High-voltage transmission lines or conductors are attached to the insulation strings’ lower part. At the same time, the top side of the suspension insulation is protected by cross arms. The most common application of suspension insulators is for “Over Head Transmission Lines.”

How many types of suspension insulators are used in electrical engineering?

Two suspension insulators are commonly used in electrical engineering for high-voltage transmission lines. Following is the name of different suspension insulators:

- Interlink suspension insulator

- Cap and pin insulator

The detail of suspension insulator types are as follows:

Interlink suspension insulator

Interlink suspension insulators are commonly known as “Hewlett type insulators.” Interlink suspension insulators are made with a special insulator called “Porcelain.” In the interlink suspension insulator, the porcelain strings are made in the way they make two curved channels, which are at 90 degrees.

These two insulation strings are interlinked with the help of U-Shaped steel. Interlink suspension insulators are stronger than any other insulator in high-voltage transmission lines.

Cap and pin suspension insulator Cap and pin type suspension insulator consists of the following parts:

- Galvanized or forged steel caps

- Porcelain

- Forged steel pins

In this type of suspension, insulator porcelain (Insulator Material) is connected with the help of a forged steel cap and locked with the use of forged steel pins.

Read More: Best Techniques To Make Your Study Sessions Enjoyable In Home Base

What are the most common applications of suspension insulators?

The main purpose of a suspension insulator is to provide electrical safety in such electrical systems where high-tension voltages are present. For example, suspension insulators are used with high-power transformers, motors, generators, electrical poles, and railway lines.

What kind of benefits can you get from a suspension insulator?

Suspension insulators are commonly used in any high-power circuit. There are a lot of benefits of suspension insulators. Following are described some benefits of suspension insulators:

Free to swing

The first advantage of suspension insulator is that you can get high flexibility from them. Because suspension insulators are hung on the pole, the hanging position allows these insulators free to swing capability.

Protection from lightning

The high voltage transmission lines connect on the lower side of suspension insulators. This position of conductor helps protect from lightning in bad or rainy weather. Lightning sometimes causes a lot of damage to the entire electrical system.

Eary repair and maintenance

The repair and maintenance of the suspension insulator are straightforward. Because the insulation discs in suspension insulators are made with porcelain, the porcelain material can be broken easily due to swinging. This is one of the major faults that happen with the suspension insulator. When any of the insulation discs break, you can remove the damaged insulation disc with a new insulation disc. There is no need to replace the complete suspension insulator.

Cost-effective

The cost of a suspension insulator is meager compared to other high voltage insulator types like “Pin Insulator.”

How are insulators classified?

It is possible to manufacture insulators from various materials, such as plastic, rubber, mica, wood, glass, etc. Several insulating materials are used in the electrical system, including porcelain, glass, steatite, polymer, ceramic, and PVC.

How do strain insulators differ from suspension insulators?

When used vertically (with the conductor suspended below), suspension insulators are called suspension insulators. When used horizontally to dead-end a conductor, strain insulators are referred to as strain insulators. Unipart suspension insulators and multipart suspension insulators are the two basic types.

Summary

So, this is the complete overview of the suspension insulator that you must know if you are working on a high voltage transmission line and need to put on insulators. Several advantages and disadvantages are attached to the use of a suspension insulator. The construction of the suspension insulator is straightforward, and you can quickly repair them. The suspension insulator provides high protection for HT (high tension) volts.