Technology has brought different changes to every aspect of our lives. Today, there are smartphones with great features used by people worldwide. People have become dependent on these technologies because they are quickly beaming information into our lives.

Have you ever thought that how technology is improving the automobile industry? Technology has made an enormous contribution to the automotive manufacturing process. Only 70 years ago, things like electronic fuel injection, power brakes, and windows were unheard of. Today these features are available in even the cheapest cars on the market. How did technology improve this industry so much within such a short time? Let’s find out below:

Better Materials Used for Cars

Suppose you want to build a wall for your house; what materials do you think will last longer- wood or bricks? Brick walls are more durable than wooden walls because they can withstand various climate conditions like rain, heat, and cold weather. Similarly, today’s cars use better quality metals like aluminum alloys instead of steel. Aluminum has a much better strength-to-weight ratio than steel. Also, aluminum can be easily molded into any shape, making it an ideal material for constructing the body of a car.

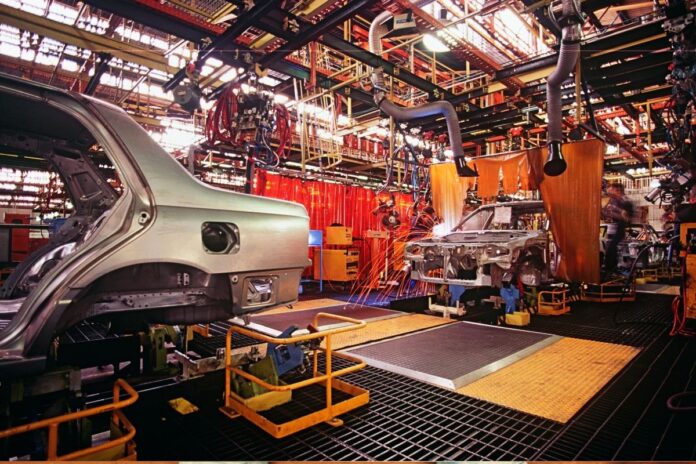

Improved Manufacturing Processes

The modern automotive industry can produce cars with high quality and low cost because of the improved manufacturing processes that are now being used by all major automakers such as Toyota and GM. These automakers use computers extensively throughout their entire production process, from design to assembly line. It allows them to minimize wastage and eliminate human errors in the manufacturing process to increase productivity and reduce costs at the same time.

Computer-Aided Design (C) Technology

It would help if you had a blueprint before you started building something. Computer-aided design (CAD) software offers to engineers and designers. With the help of CAD, you can design a car’s body using a computer in 2D or 3D. You can also create digital models of various parts, including engine assembly, suspension system, security system with quality dashcams, etc. Using such technology, any changes in the design can easily be made without incurring any extra cost because it helps save time and money in the development process. For example, GM used CAD extensively during its redesigning phase when developing the Chevrolet Volt from 2010 to 2015.

Computer-Aided Manufacturing Technology (CAM)

CAM is an advanced version of CAD software that includes special tools that machine operators use. These tools tell the machines what to do and where to start cutting, drilling, etc.; before the actual manufacturing process begins, there is no chance of making any human errors while cutting or welding parts together. This technology has made it possible for car manufacturers to produce various customized parts quickly while minimizing wastage due to faulty designs.

Reducing Cost & Increasing Productivity

Automakers can reduce costs both for end-users and themselves using these new technologies in the production process because they help improve productivity at the same time. For example, Toyota increased its production capacity from 6 cars per hour in 1985 to 26 cars per hour in 2011 using CNC machines that cut components with laser beams instead of conventional machines which used manual labor to cut parts. Similarly, Ford Motor Company uses robots to assemble car components like brakes and transmissions in its new factory in Valencia, Spain.

Dropping Unnecessary Features

Automakers are also dropping unnecessary features from their vehicles to make them more affordable for the end users while maximizing profits at the same time. For example, Volkswagen announced that it would be discontinuing some of its slow-selling models like Routan minivan in the US market soon due to falling sales. Manufacturers are also bringing back smaller cars with gasoline instead of diesel or electric engines because customers are looking for low-cost fuel-efficient options these days, not just quick acceleration or improved mileage per gallon figures. Compact size is an added advantage because it makes parking easier, especially in crowded cities. It is a good example of how new technology has lowered the cost of transportation for everyone without impacting performance or quality.

Wrapping Up!

The modern automotive industry has evolved enormously, thanks to new innovative technologies constantly being developed by automakers worldwide. Although these technologies have changed the way things are done in the manufacturing process, they have made cars extremely profitable. It also provides job opportunities for many skilled and unskilled workers worldwide.

As technology continues advancing every day, we can expect much more innovation in automobile manufacturing over the next few decades. Maybe someday, very soon, we will be driving flying cars instead of normal ones, or maybe not! Who knows?